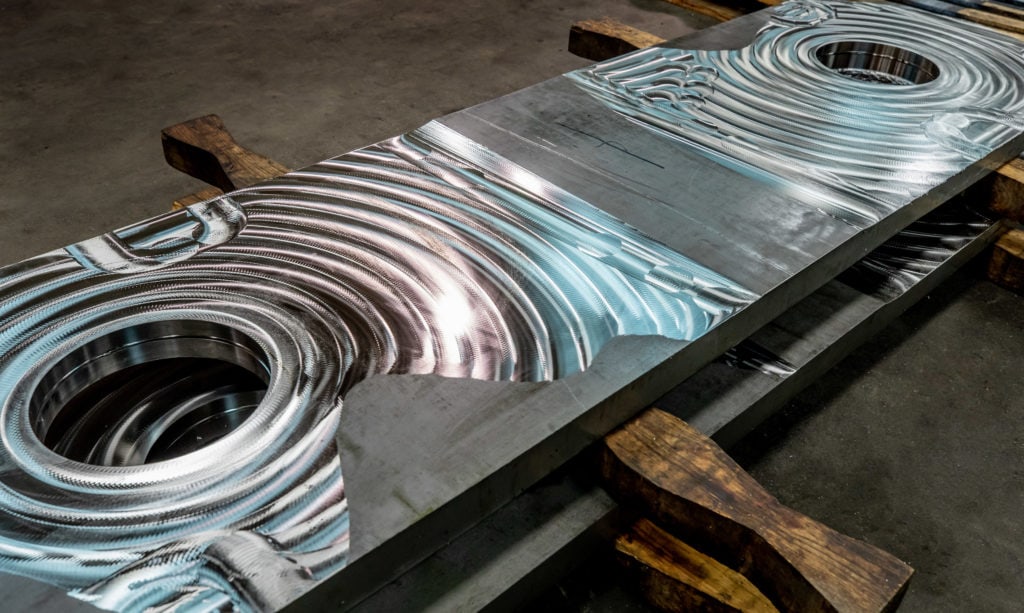

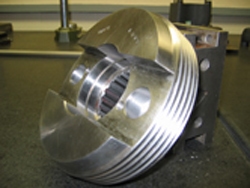

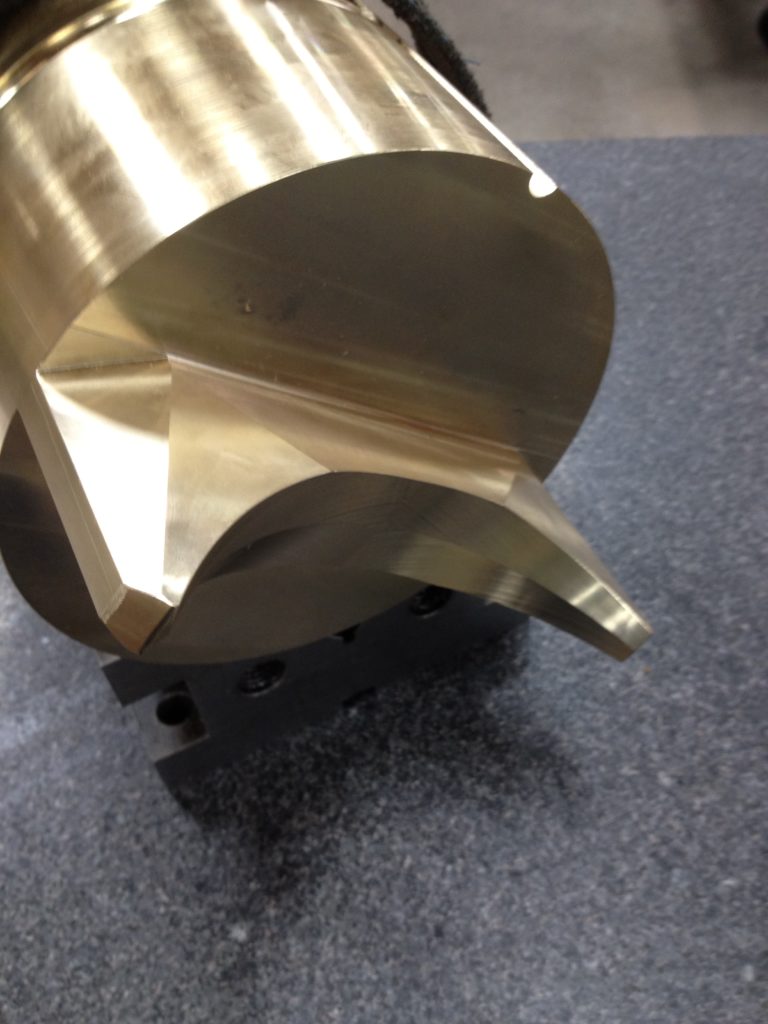

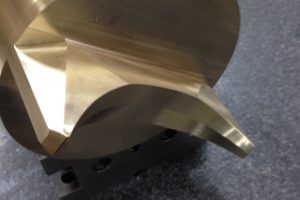

With our custom CNC vertical and horizontal milling technology we are able to specialize in CNC machining on small and large parts alike. Across our multiple machining centers we have work envelopes ranging from 20x20x40” to 24x36x200″.

Most of these machines are equipped with 4-axis capability, allowing us to offer a unique machining envelope for the most advanced parts you may have. Most of our milling centers have fixed tables, which allow us to machine parts much larger than the standard work envelope.

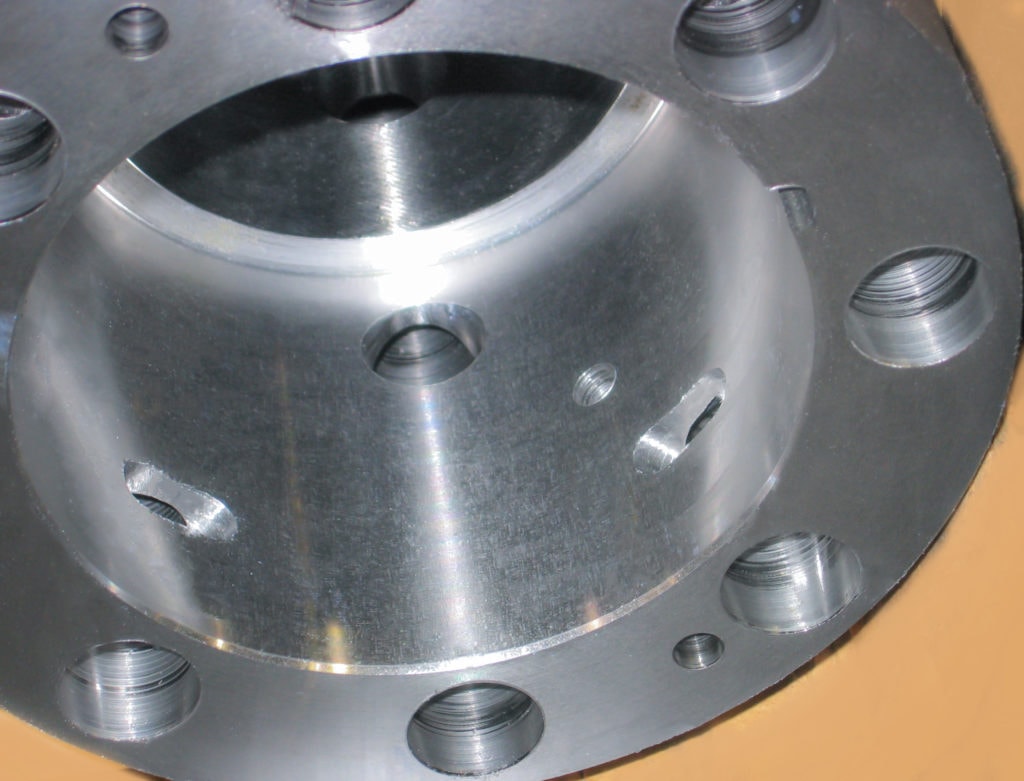

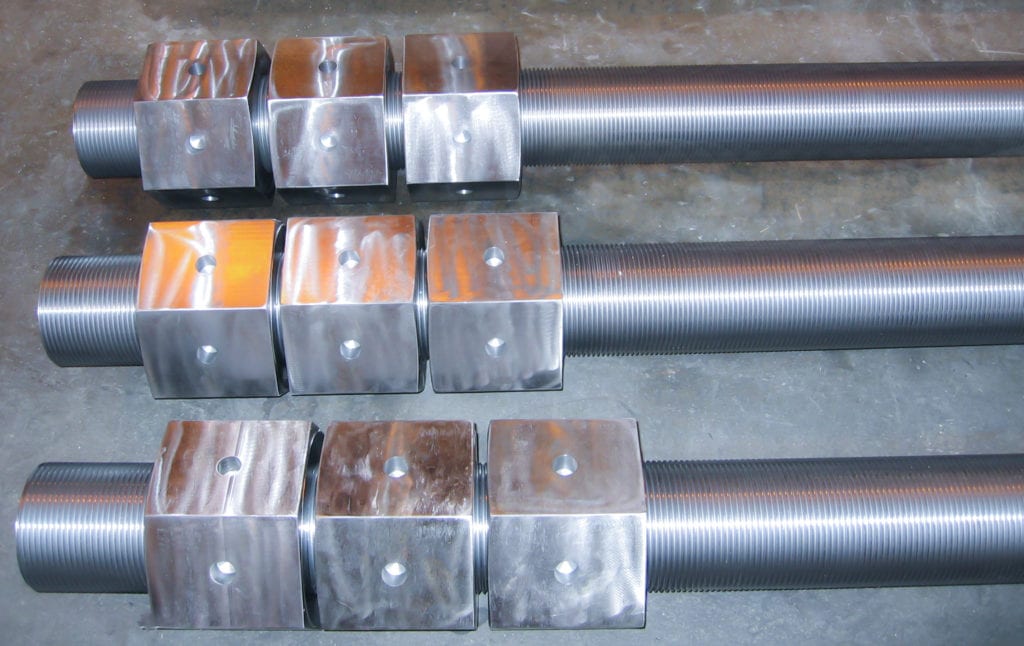

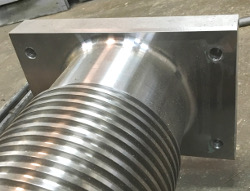

Helical forms, long keyways and intricate shapes on large parts are just some of the unique processes frequently machined by Jerpbak-Bayless. Our advanced CNC milling services are ISO compliant and hold +/-.0005″ precision tolerance to meet high customer expectations. We also offer a variety of Specialty Machining and secondary operations.