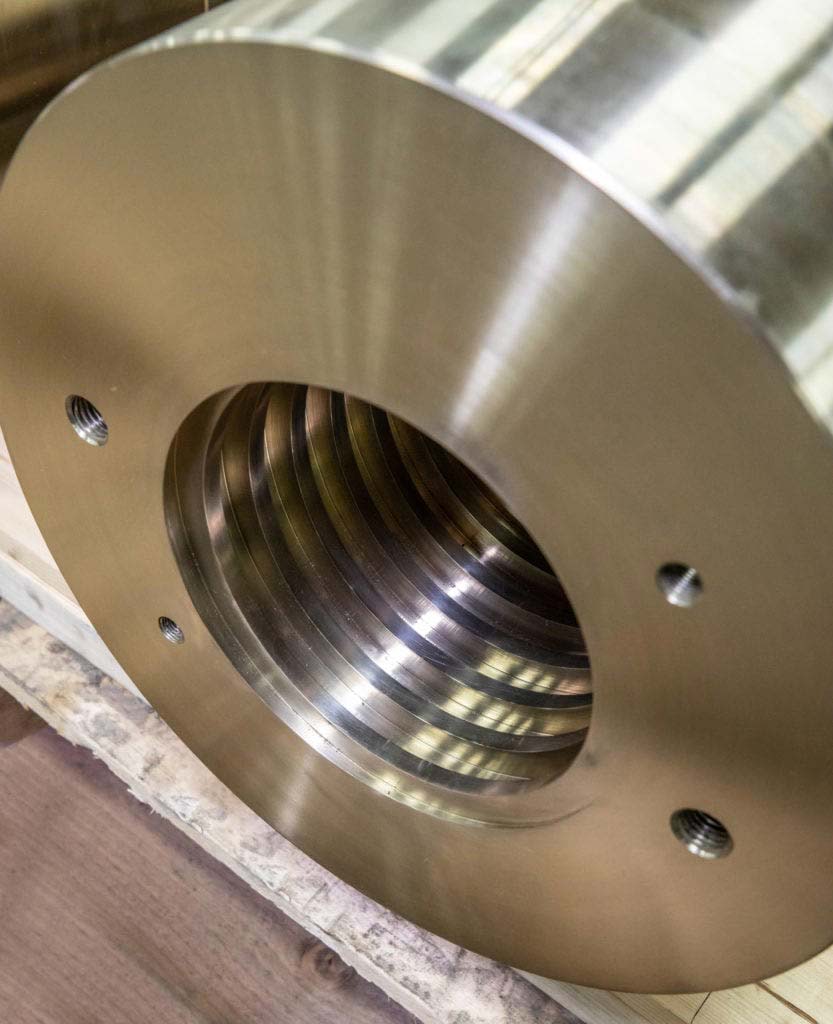

Jerpbak-Bayless provides superior custom threading including ACME, buttress, API, square, trapezoidal, all forms of V-threads and of course standard 60-degree threads both internal and external.

Our equipment inventory includes a variety of precision thread cutting machines, many of which have been retro-fitted to cut much more advanced thread forms than previously possible. Our largest thread milling machine is capable of cutting threads 228″ long in one setup. For parts with 6″ diameter or less, we can work with essentially unlimited length. For larger diameter requirements, we have specially adapted CNC lathes that can handle most standard and special thread forms up to a 40″ diameter and a 200″ part length.

With our portable CMM, we can inspect many aspects of your custom threads right in the machine, holding +/-.0005″ precision tolerance and .0003″ concentricity. Jerpbak-Bayless can also perform pre and post-machining services on your threaded or non-threaded parts. Learn more about our Specialty Machining and secondary operations.