At Jerpbak-Bayless Company, we are proud to work with our OEM customers to provide them with a variety of highly-specialized component parts, allowing them to maximize value to their customers.

Portfolios

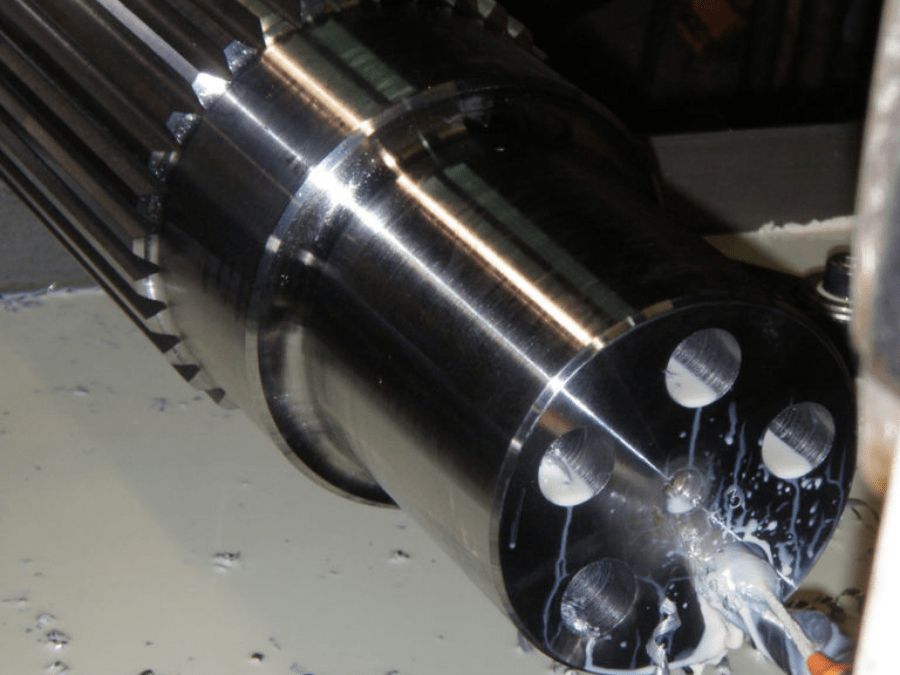

We machined three separate ANSI involute splines, all timed together.

Spline Drive Shaft

4340 Alloy Steel Spline Drive Shaft Used for Deep Mining

Using a variety of cutting processes, such as splining, CNC turning, and CNC milling, Jerpbak-Bayless was able to produce a series of spline shafts designed to be used specifically for deep mining.

- 4340 alloy steel pre-heat treated to 38Rc

- 7.5″ diameter, 127″ long, 1590 lbs

- .0005″ tolerance held throughout

- 16 Ra bearing surface finish

- 3 ANSI involute splines timed together

Our well-equipped facility produced these parts complete and was able to manufacture 10 parts per month over a 12-month timeframe, per customer requirements. Using a combination of our advanced turning, splining, and milling services, we provided a quality product in a relatively short time frame.

Capabilities: Spline, CNC Turning & CNC Milling

We designed a machined and welded joint, creating a 39 foot long finished part.

ACME Lead Screw

4140 Alloy Steel Very Long Acme Lead Screw for Oil & Gas Exploration

A client in the Oil & Gas Exploration industry requested the manufacture of a unique very long ACME lead screw. Material of the necessary length was not available in the United States, so we designed a machined and welded joint, allowing us to secure two pieces of steel together and construct a long screw that matched requested shaft dimensions.

- 4140 alloy steel pre-heat treated to 28-32Rc

- 3.75″ diameter, 39 feet long, 1400 lbs

- .001″ diameter tolerance

- 32-125 Ra surface finish range

- 36.5 feet of class 2g ACME thread

We used our welding expertise and advanced turning and milling machinery to afford the client with a suitable solution to their problem, producing and delivering fully assembled extra-long ACME lead screw within seven weeks of request.

Capabilities: CNC Turning, CNC Milling, Threading & Welding

We manufactured critical infrastructure components for the New Jersey Turnpike.

Bridge Link Plates

High Chrome & Nickel Stainless Steel Plates for Bridge Construction Industry

We produced a number of connector plates for an engineering firm working on bridge rehabilitation on the New Jersey Turnpike. The plates are used in pairs with connector pins, also made in house. Each 12.250” diameter hole was bored at a unique angle to the rest of the plate and the hole-to-hole center distance was held to exacting tolerances. Each hole had a gun-drilled lubrication hole and channel.

- Nitronic 60 austenitic stainless steel

- 34.0” wide, 119.0” long, 3.0” thick, 3000 lbs

- .005” tolerances held throughout

- 32 Ra bore finishes

- Angle offsets held to 1/8th degree on bore centerlines

Jerpbak-Bayless maintained a strict delivery timeline to allow bridge rehabilitation to complete on time and at the quality level required.

Capabilities: CNC Milling, Boring, Gun-Drilling

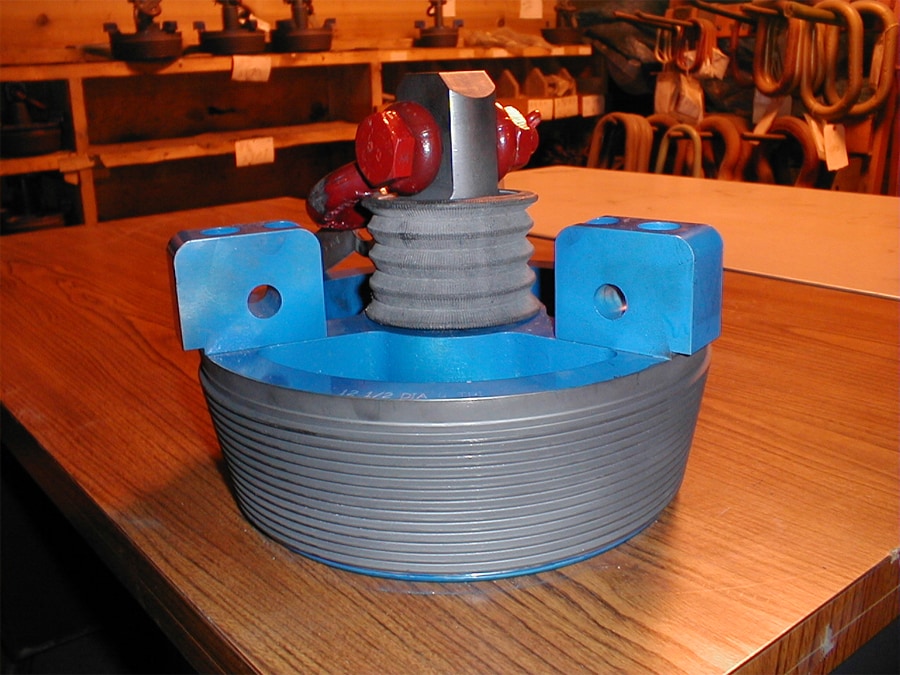

Our design allowed for a 20-60% reduction in customary weight.

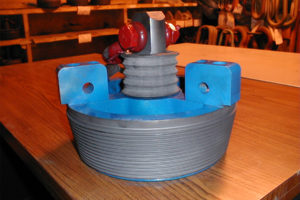

Threaded Lifting Connectors

Aluminum & Steel Threaded Lifting Connectors for the Steel Manufacturing Industry

We designed and built a series of threaded lifting connectors with the goal of maximizing the service life while reducing the customary weight. These were produced to meet monthly client usage requirements.

- Aluminum and heat treated alloy steel

- 4-17″ diameter, 8″ length, 25-75 lbs

- .001″ tolerance

- 62 Ra thread surface finish

- Designed for 20-60% weight reduction

After the connectors were assembled we conducted a strength test, ensuring that our products were designed and assembled to the highest quality standards.

Capabilities: CNC Turning & CNC Milling