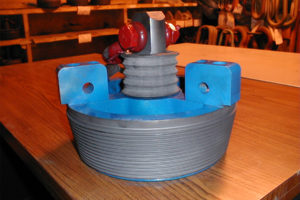

Using our advanced CNC turning and milling services, Jerpbak- Bayless was able to design and build a series of special threaded connectors to be used by the steel manufacturing industry. By constructing each part out of a combination of 6064 – T6 aluminum and 4340 HT steel, we were able to maximize the service life of our unique products while reducing the customary weight, as each of our newly designed connectors weighed between 20 and 60% less than the prior designs.

All these threaded connectors measured eight inches in length and 4 to 17 inches in diameter. With a 62 RMS thread surface finish, each piece was built while upholding a .001 inch tolerance. After the connectors were assembled, we then used a pull test to inspect the strength and integrity of the threads, ensuring that our products were designed and assembled to the highest quality standards.

Inspecting each part to a thread gage, we guarantee that our special connectors meet NEMA standards. And, we produce 5-10 pieces per month within a five week lead time. By employing our superior CNC turning and milling service, and combining steel and aluminum an added benefit was a longer sustainable service life. We were able to assemble threaded connectors that met absolute client satisfaction.