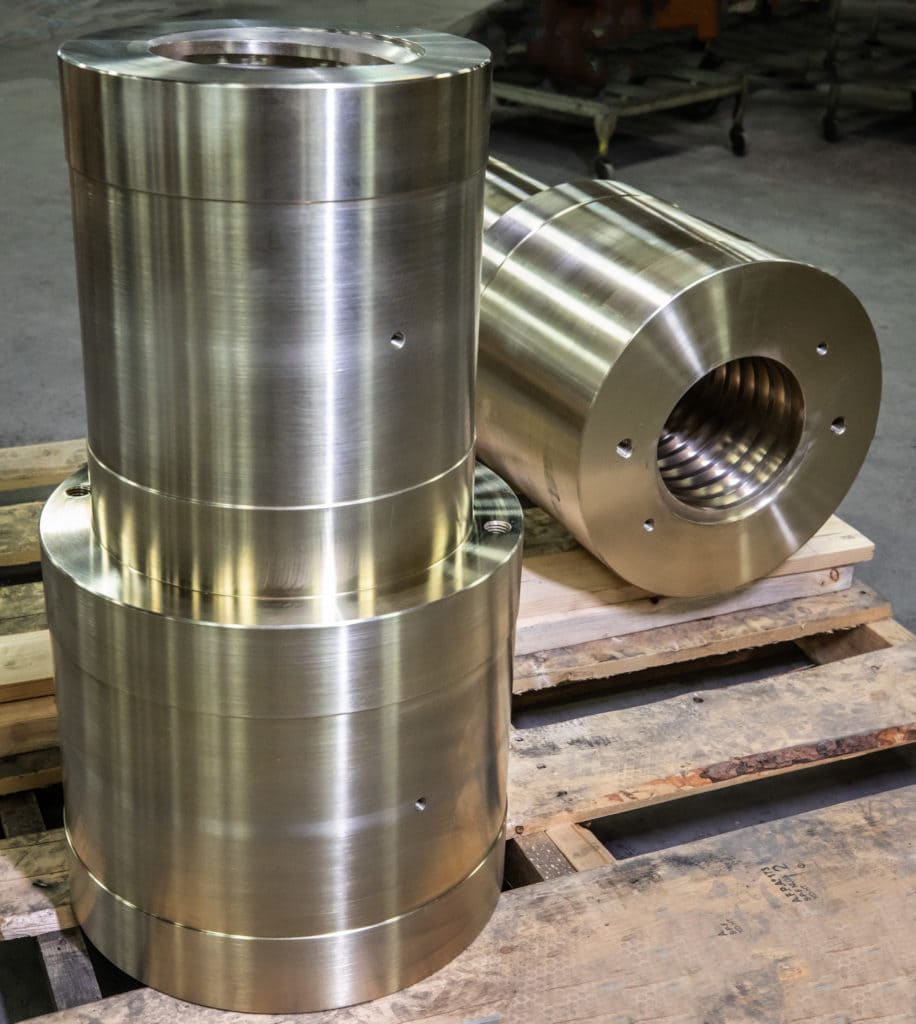

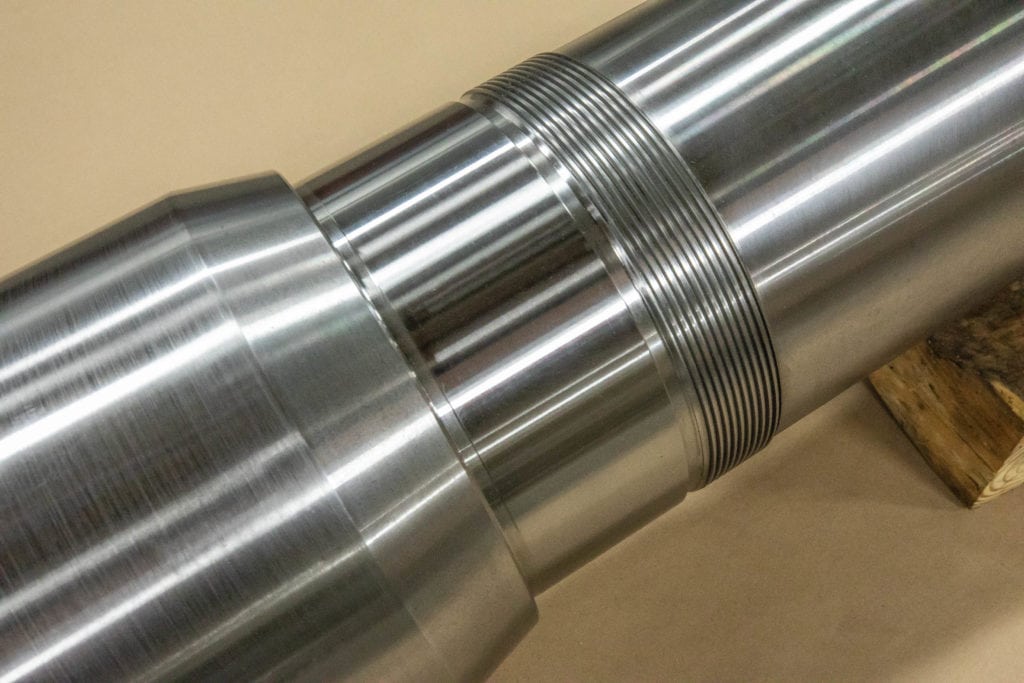

Jerpbak-Bayless machines a variety of medium to large shafts and regularly cuts unique thread forms that few others can. Across our numerous CNC turning centers, we have capabilities ranging from 20″ swing with a 60″ center distance to 40″ swing with a 200″ center distance.

Our advanced turning center capabilities include:

- Deep boring

- 5-axis mill/turn

- Turn-through steady rests

- Large spindle through-holes for extra long parts

With our innovative CNC turning equipment, Jerpbak-Bayless can hold +/-.0005″ precision tolerances to meet your most extreme turning requirements. We also offer a number of long-bed engine lathes that can handle many secondary operations to keep your jobs running efficiently. Learn more about our additional Specialty Machining and secondary operations.