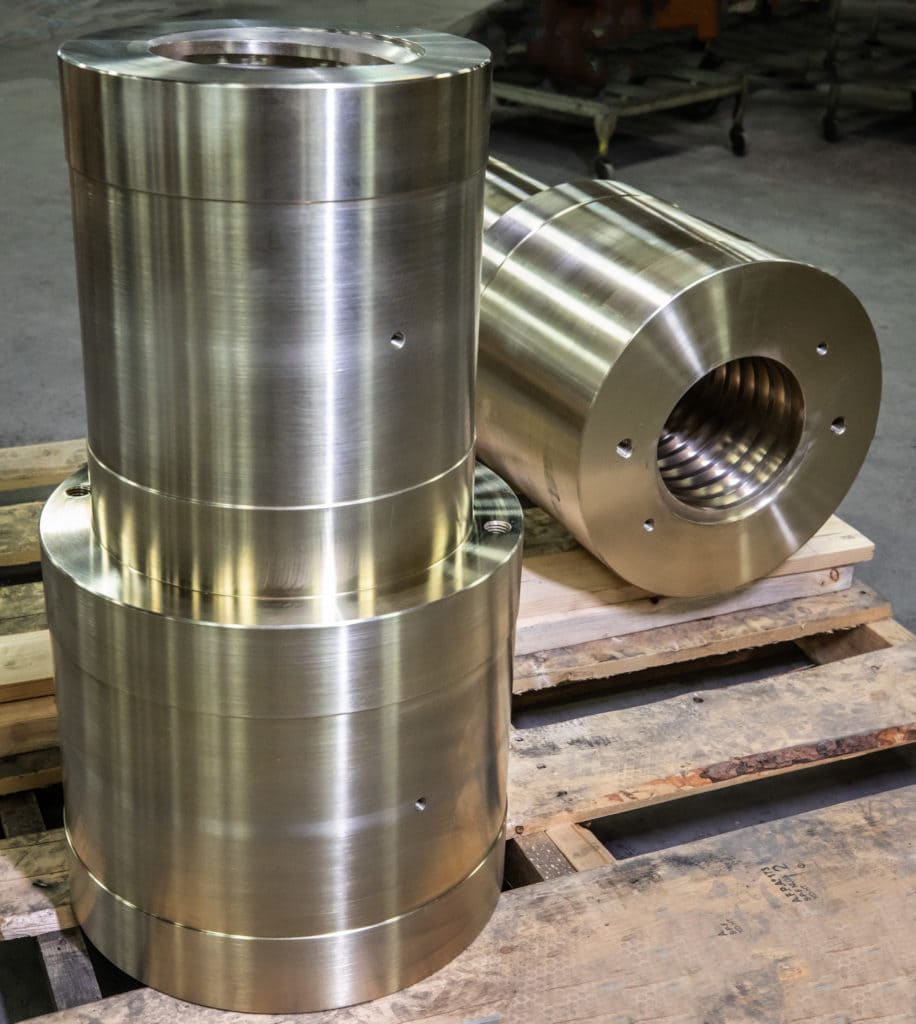

If you’re looking for the best CNC turning services and related metal machining solutions, our team at Jerpback-Bayless Company is here to help. From high-level CNC turning to 5 axis CNC machining and various related services, we have the expertise and equipment to meet your needs.

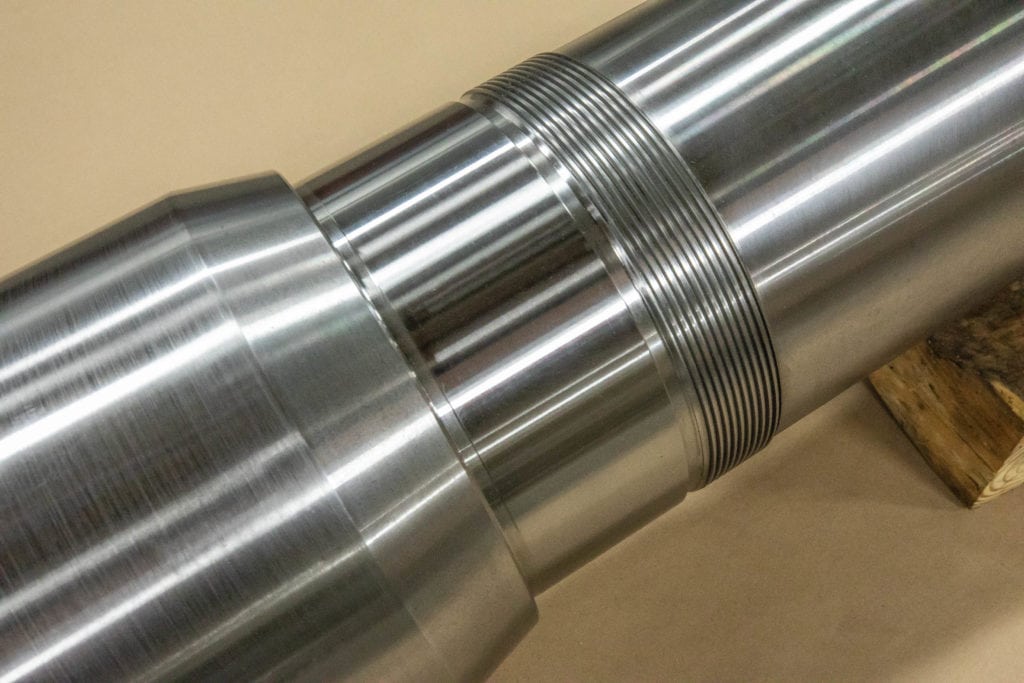

With applications ranging from pump and axle shafts to tie bars, threaded shafts and more, our CNC turning services are versatile and efficient. Our state-of-the-art equipment allows us to produce high precision parts with tight tolerances, ensuring that your project is completed accurately and on time. Contact us today to learn more about any of our CNC turning or metal machining services!

Our Capabilities

Jerpbak-Bayless machines a variety of medium to large shafts and regularly cuts unique thread forms that few others can. Across our numerous CNC turning centers, we have capabilities ranging from 20″ swing with a 60″ center distance to 40″ swing with a 200″ center distance.

Our advanced turning center capabilities include:

- Deep boring

- 5-axis mill/turn

- Turn-through steady rests

- Large spindle through-holes for extra long parts

With our innovative CNC turning equipment, Jerpbak-Bayless can hold +/-.0005″ precision tolerances to meet your most extreme turning requirements. We also offer a number of long-bed engine lathes that can handle many secondary operations to keep your jobs running efficiently. Learn more about our additional

Specialty Machining and secondary operations.