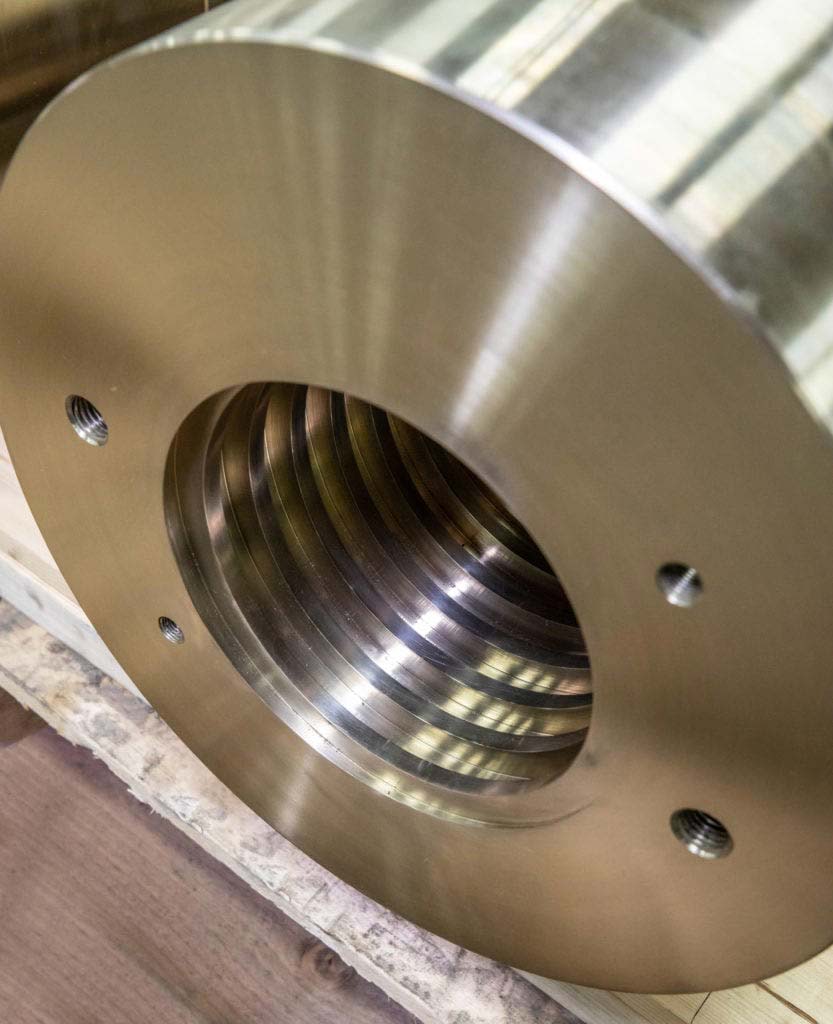

If you need threads that fit right, run smoothly, and hold up under real working conditions, you’re in the right place. Jerpbak-Bayless Company provides custom threading for customers who can’t rely on off-the-shelf solutions. Whether your part is long, oversized, non-standard, or built for heavy service, we machine threads that perform the way you expect them to.

Custom threads often sit at the center of motion, load transfer, or positioning. When threads fail, the whole system feels it. That’s why customers come to Jerpbak-Bayless for custom threaded parts that work the first time and keep working over the long haul.

Built for Real-World Threading Challenges

Some threading jobs look simple on paper and turn difficult fast once the machine starts running. Long lengths, tight tolerances, special forms, and heavy materials all demand experience. Custom threading is a core capability at Jerpbak-Bayless, backed by decades of hands-on machining knowledge.

We take on threading jobs that others avoid, including parts with extreme lengths, large diameters, or uncommon thread forms. From one-off components to repeat production runs, we focus on consistency, accuracy, and repeatable results.

Thread Forms We Machine

Jerpbak-Bayless produces a wide range of custom threaded parts, both internal and external. Common thread forms include:

- ACME threads

- Buttress threads

- API threads

- Square threads

- Trapezoidal threads

- Standard and non-standard V-threads

Each thread form serves a purpose. Some handle high loads. Some control motion. Some manage wear over repeated cycles. We help customers select thread forms that match the job, material, and operating environment.

Custom Threading Capacity and Part Size

Thread length and diameter limits can stop many projects before they start. Our equipment removes those barriers. Jerpbak-Bayless machines long threads in a single setup, which improves accuracy and alignment across the full length of the part.

We handle small diameters, large diameters, and extended lengths that exceed common machining limits. This flexibility allows us to produce custom threaded parts for large industrial assemblies, motion systems, and heavy equipment without breaking the job into multiple operations.

Threading Methods That Fit the Job

No single process works for every thread. That’s why we offer multiple custom threading methods, including:

- Thread milling

- Thread cutting

- Thread grinding

Each method is chosen based on material type, tolerance requirements, surface finish, and part geometry. The goal is smooth engagement, controlled wear, and dependable performance in service.

Materials for Custom Threaded Parts

Material choice affects thread life, strength, and wear. Jerpbak-Bayless machines custom threaded parts from a range of metals, including:

- Carbon steel

- Alloy steel

- Stainless steel

- Other specialty metals as required

If material selection is still open, we help review options based on load, environment, and duty cycle.

Tolerances and Inspection

Threads need more than correct pitch. They need alignment, concentricity, and consistent form from end to end. Our custom threading work is backed by detailed inspection using precision measuring equipment, including portable CMM technology.

This approach supports tight dimensional control and reliable fit with mating components, even on long or large-diameter threads.

Common Applications

Customers rely on Jerpbak-Bayless for custom threaded parts used in:

- Jack screws and lifting systems

- Valve screws and actuators

- Lead screws and motion control components

- Levelwind and reversing screws

These parts often carry heavy loads or operate continuously. Thread accuracy plays a direct role in safety and service life.

One Source for Custom Threaded Parts

Custom threading is often one step in a larger machining process. Jerpbak-Bayless offers turning, milling, grinding, and secondary operations to deliver finished custom threaded parts from a single source. That keeps schedules tight and communication clear.

Talk With Jerpbak-Bayless About Your Custom Threading Needs

If your application calls for precision, durability, and experience, Jerpbak-Bayless Company is ready to help. Contact us to discuss your custom threading requirements, request a quote, or review a challenging threaded design with our team.