At first glance, ACME threads and trapezoidal threads appear very similar. In fact, they do have numerous similarities, including purpose and time of development, which make them suitable for many of the same applications. However, they do have some differences which can affect when you may want to use them. For example, ACME threads were developed with regard to Imperial units, so they are commonly used in the United States. On the other hand, trapezoidal threads were developed with regard to metric units, so they are standard for European countries.

Below, we go more in-depth into the history, advantages, and applications of these two thread types to help readers better understand when they may want to use one over the other.

What Are ACME Threads?

Prior to the design of ACME threads in the late 19th century, square threads were the industry standard for applications involving motion transfer or heavy loads. However, despite their widespread use, they had some significant disadvantages. For example, they were fairly weak, which was not ideal for demanding applications. Additionally, they were difficult for manufacturers to produce at the time. These challenges led to the development and adoption of ACME threads in the late 1800s.

Prior to the design of ACME threads in the late 19th century, square threads were the industry standard for applications involving motion transfer or heavy loads. However, despite their widespread use, they had some significant disadvantages. For example, they were fairly weak, which was not ideal for demanding applications. Additionally, they were difficult for manufacturers to produce at the time. These challenges led to the development and adoption of ACME threads in the late 1800s.

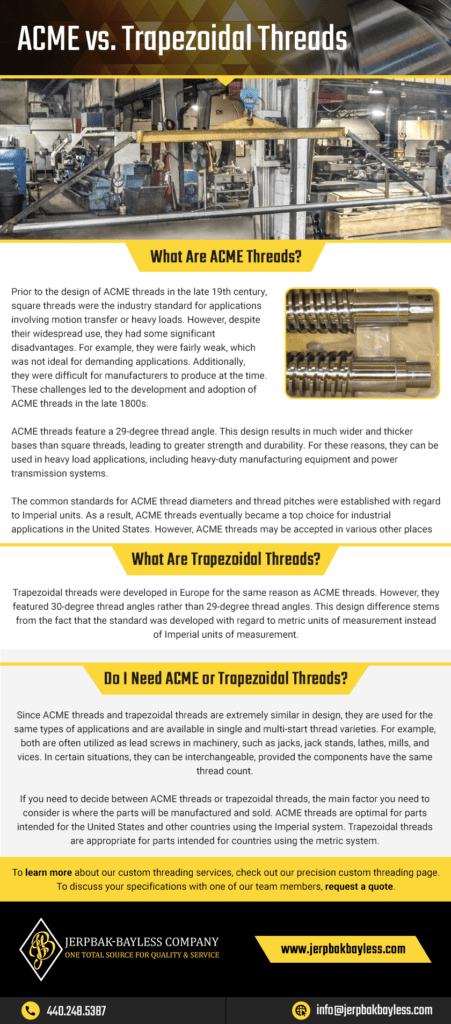

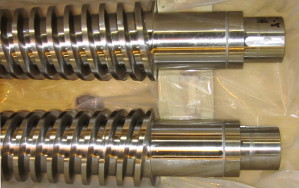

ACME threads feature a 29-degree thread angle. This design results in much wider and thicker bases than square threads, leading to greater strength and durability. For these reasons, they can be used in heavy load applications, including heavy-duty manufacturing equipment and power transmission systems.

The common standards for ACME thread diameters and thread pitches were established with regard to Imperial units. As a result, ACME threads eventually became a top choice for industrial applications in the United States. However, ACME threads may be accepted in various other places across the globe.

What Are Trapezoidal Threads?

Trapezoidal threads were developed in Europe for the same reason as ACME threads. However, they featured 30-degree thread angles rather than 29-degree thread angles. This design difference stems from the fact that the standard was developed with regard to metric units of measurement instead of Imperial units of measurement.

Do I Need ACME or Trapezoidal Threads?

Since ACME threads and trapezoidal threads are extremely similar in design, they are used for the same types of applications and are available in single and multi-start thread varieties. For example, both are often utilized as lead screws in machinery, such as jacks, jack stands, lathes, mills, and vices. In certain situations, they can be interchangeable, provided the components have the same thread count.

If you need to decide between ACME threads or trapezoidal threads, the main factor you need to consider is where the parts will be manufactured and sold. ACME threads are optimal for parts intended for the United States and other countries using the Imperial system. Trapezoidal threads are appropriate for parts intended for countries using the metric system.

Learn More About Threads From Jerpbak-Bayless Company

Want additional information on ACME threads and trapezoidal threads? Ask the experts at Jerpbak-Bayless Company! We are a precision machining company with extensive experience providing superior custom threading services. From ACME threads to trapezoidal threads to square threads, we do it all. If you have any questions or concerns about a particular thread type or threads in general, we can answer and address them.

Looking for a threading partner for your next project? We’ve got you covered. Equipped with a vast equipment inventory, including precision thread cutting machines, we create a range of threaded parts and products. Our capabilities include:

- Threading processes: thread grinding, thread milling, thread cutting, multi-start threads

- Part length: unlimited lengths

- Part outer diameter: 1.5–34 inches

- Roundness: Up to .0001 inches

- Concentricity: Up to .0003 inches

- Tolerance: ±.0005 inches

- Production volume: 1–1000 pieces

To learn more about our custom threading services, check out our precision custom threading page. To discuss your specifications with one of our team members, request a quote.